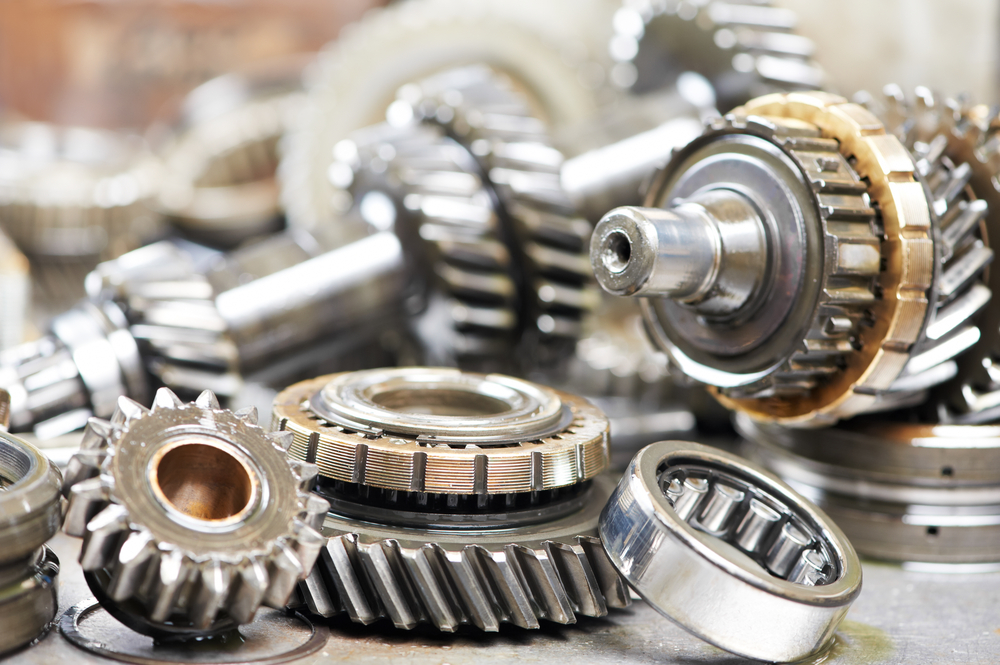

Tougher Bearings, Bushes and Gear Motors

Wear-Resistant brass alloys for high demand applications

Super strength brass alloys which retain good machining and formability and have superior physical and mechanical properties

The Technology

is available under licence for free

Without doubt, brasses and bronzes are the most widely utilised family of materials on the planet.

This technology is a leap ahead for brass alloys. ‘Low-Cost High Entropy Brasses’ (HEBs) with their unique alloy composition are up to 20% cheaper to produce and have the potential to change the market landscape for standard bearings, bushes, gears and cogs made of traditional brasses.

These alloys consist of varying mixtures of copper, nickel, manganese, zinc, aluminium and tin allowing for specific tailoring of cost, strength, wear and corrosion resistance and display the same self-lubricating properties as typical brass.

Key Benefits

• Cheaper – lower $/kg of constituent alloys

• Machinable/Formable – similar machining characteristics and higher forming ductility than standard brasses (suitable for forging).

• Harder than traditional brasses giving superior/longer wear capabilities

• Superior mechanical strength and lighter than traditional brasses leading to less material required to produce a component and higher component efficiency

Applications

• Standard bearing housings and bearing bushes for heavy automotive applications

• Bushes/bearings for small electrical appliances and hand held tools.

• High performance, low-cost gears & cogs for motorised/rotating consumer electrical appliances

Opportunity

This technology is available as an Easy Access licence to companies and individuals within the field.

Lead Researcher

Dr Kevin Laws

School of Materials Science and Engineering

A PDF Print version of this technology is available here