UNSW has boosted the performance of its Laser Doping Selective

Emitter (LDSE) solar cell, a ground-breaking technology first developed by UNSW

engineers

The Technology

The LDSE technology utilizes the properties of a laser in the presence of a

phosphorus doping source to melt a silicon wafer. This process incorporates

phosphorus dopants into the molten silicon thereby exposing the silicon surface.

Subsequent self-aligned metal contact formation is achieved with light-induced

plating. Novel firing conditions used in the LDSE technology facilitate

the achievement of Voc values approaching 700mV on standard commercial grade

p-type CZ material.

Consequently, metal lines are only 20 microns wide, and have perfect

alignment to localised heavily doped regions. The antireflection coating is

retained in non-metallised regions and acts as a plating mask, providing

excellent surface passivation and antireflection qualities.

LDSE avoids degradation problems associated with high temperature thermal

processing; shading loss caused by wide lines, and eliminates the use of

expensive silver pastes.

Key Benefits

The advantages of UNSW’s patented LDSE solar cell technology are:

- Higher efficiency solar cells

- Lower production costs

- Suitable for mono - or multi-crystalline wafers

- Suitable for p-type and n-type wafers with either front or rear

junctions

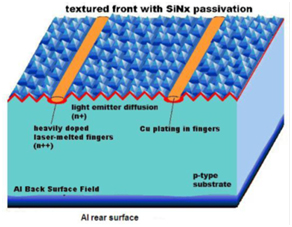

Diagram

of a p-type LDSE solar cell

The Opportunity

LDSE technology can be retrofitted to Screen Print Lines, allowing

application of the technology readily achievable for commercial lines.

NewSouth Innovations is seeking licensees for the LDSE technology as well as

collaborative research partners to take the advanced LDSE technology for

double-sided and bifacial solar cells to market.