UNSW has developed new dielectric patterning techniques to replace

photolithography. Less steps, less and cheaper chemicals for manufacturing high

efficiency solar cells.

The Technology

UNSW holds the world record for the efficiency of single junction silicon

solar cell. The record of 25.0% was achieved using photolithography, which is

too expensive for large scale commercial implementation.

The UNSW patterning techniques, which use inkjet printing or aerosol jet

printing, are cheaper than photolithography. They avoid the use of expensive

masks and mask aligners.

Digital images represent the etching patterns, so they are easily prepared

and changed. The etching pattern is printed to form openings in a dielectric

layer of silicon dioxide or PECVD silicon nitride.

The ‘resist’ technique typically etches grooves of 45 μm width, and holes ~40

μm in diameter. A single resist layer can be used for multiple patterning

processes.

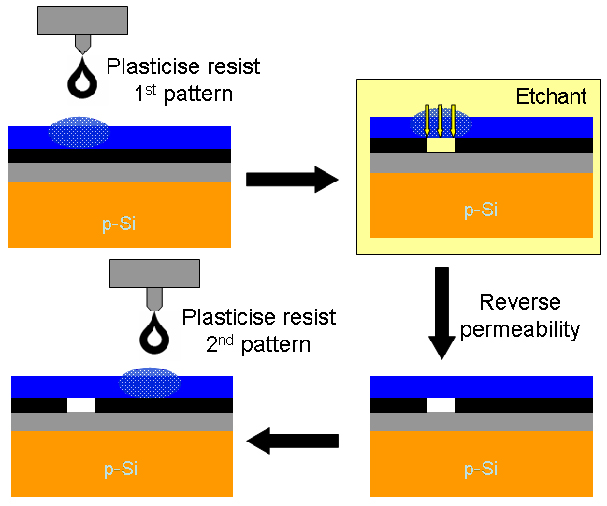

How it works:

- A resist layer is formed over the dielectric surface.

- Patterned deposition of a plasticizer forms permeable regions

in the resist layer.

- Aqueous etchants then permeate through the patterned resist areas, and

etch openings in the dielectric layer.

Process of patented ‘resist’ technique

The ‘direct’ technique, requires fewer steps and uses less and cheaper

chemicals than photolithography.

How it works:

1. An acidic polymer layer is formed over the dielectric surface.

2. A pattern of non-corrosive fluoride ions is deposited onto the

polymer

3. The fluoride ions react with the polymer to form

hydrogen fluoride (HF) locally, which then etches the underlying dielectric

layer.

Key Benefits

- Grooves narrow as 25 μm etched in a 75 nm thick PECVD silicon nitride

layer using an aerosol jet printer

- Immersion etching step is not needed so therefore largely reduced

quantities of toxic and corrosive etching fluid.

- Etched regions can be metal plated to form front metal contacts to the

solar cell.

- Significant OH&S advantages by reducing operator training expenses and

waste disposal issues.

- Other uses such as enhanced light capture into the cell by texturing the

silicon surface with dielectric masks created using UNSW’s dielectric

patterning techniques.

Opportunity

Collaborative partnership with UNSW to introduce production of high

efficiency solar cells for large scale commercial production.

More Information and Contact Details: PDF

verison of Non-Confidential Disclosure Document